I received some new ball bearings last week since my old ball bearings bought last year wore already.

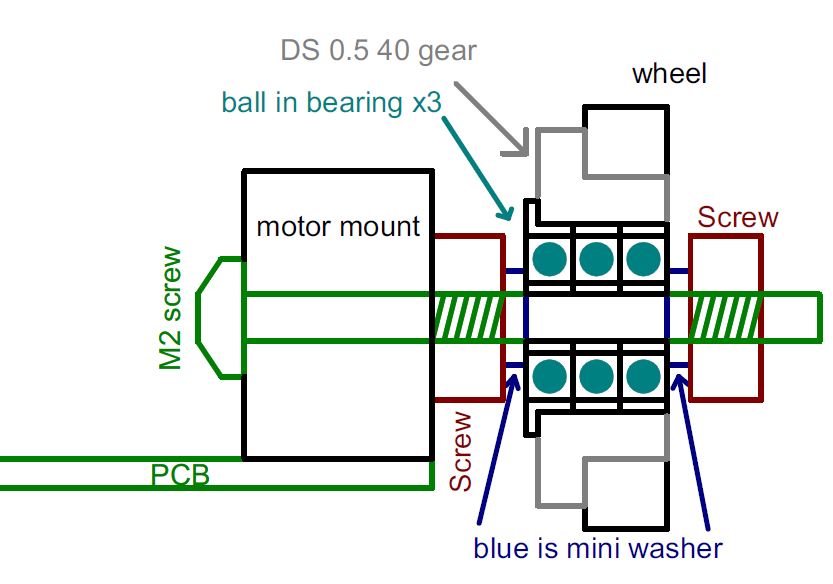

In order to simplify the the ball bearing install difficulty, I used 1 flanged 2×5 flanged ball bearing and 2 non-flanged ball bearings for each wheel. In this case, a perfect size spacer is no longer needed to support inner race if I want to use 2 flanged ball bearings to support one wheel. Of course, the only disadvantages are you need spend a little bit more money on both flanged and non-flanged ball bearing, but you don’t need to worry if you can find proper spacer between 2 bearings anymore.

here is the a sketch how my motor mount was assembled:

there are 3 ball bearings inside of the bore of DS-0.5 40 gear, the left most one is a flanged ball bearing, the rest 2 are non-flanged. Since they are 2x5mm ball bearing, the outer diameter for spacing mini washer shouldn’t be larger than 4mm, I only found this one meet my requirement online http://www.helipal.com/h50187-m2-5-socket-collar-screw.html. The washer came with 4 socket collar screws, and there are 4 washers per package, so 8 washers will be needed for a 4 wheel micromouse at least.

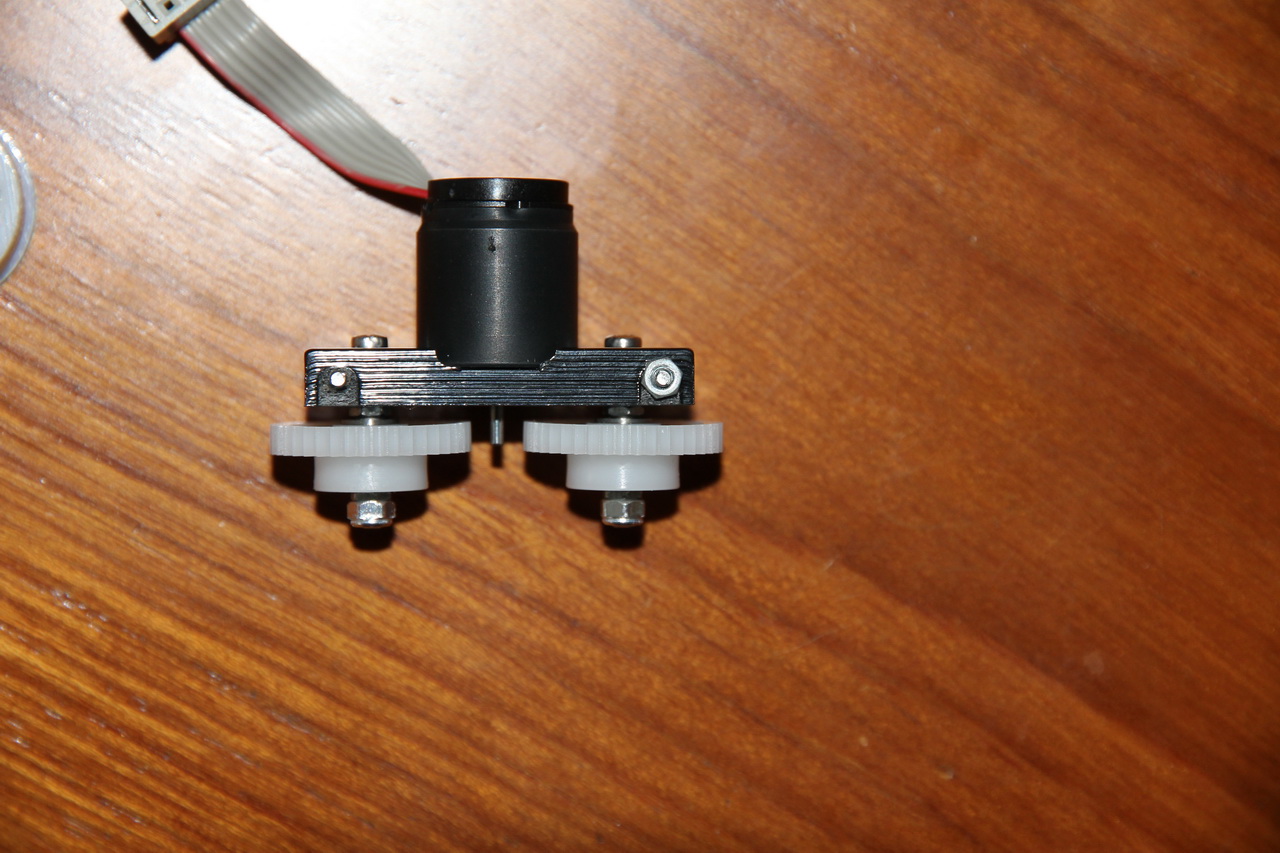

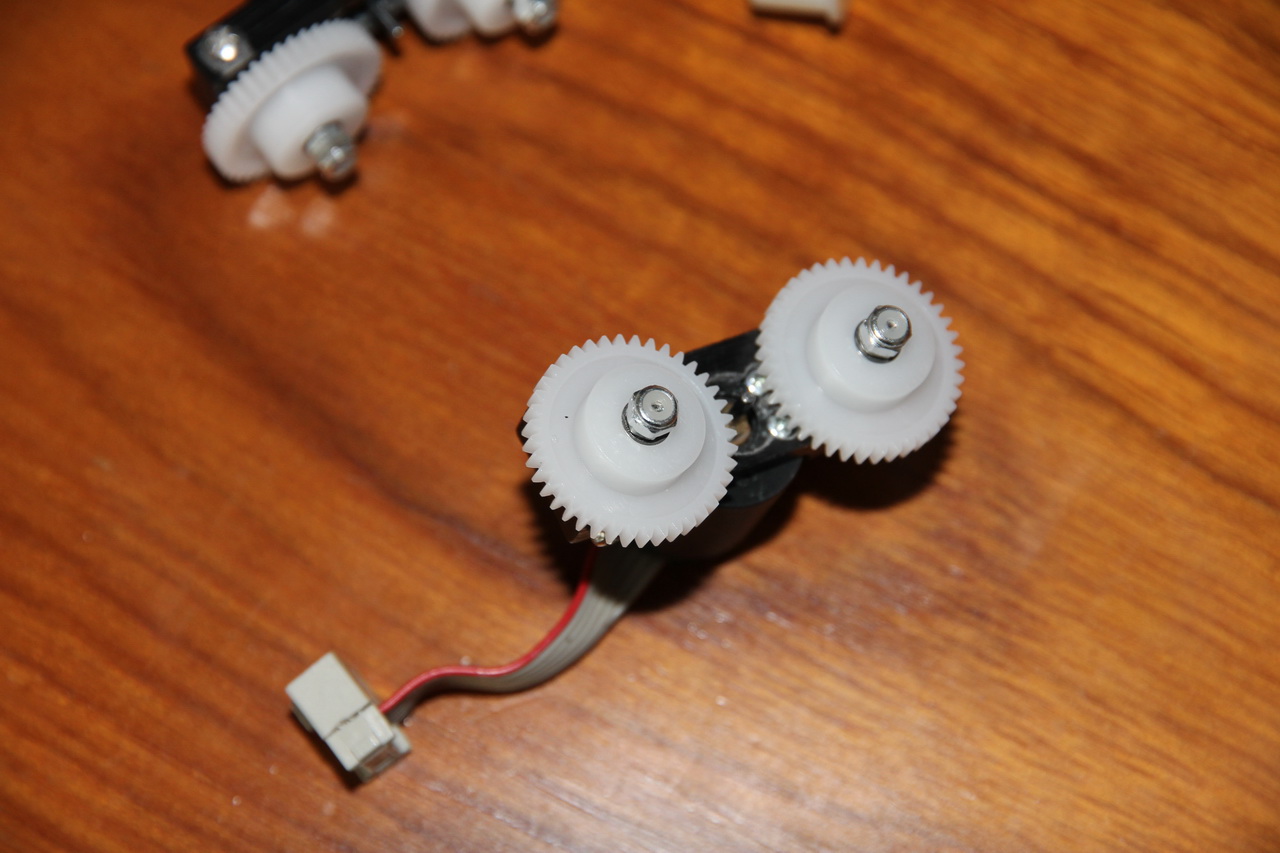

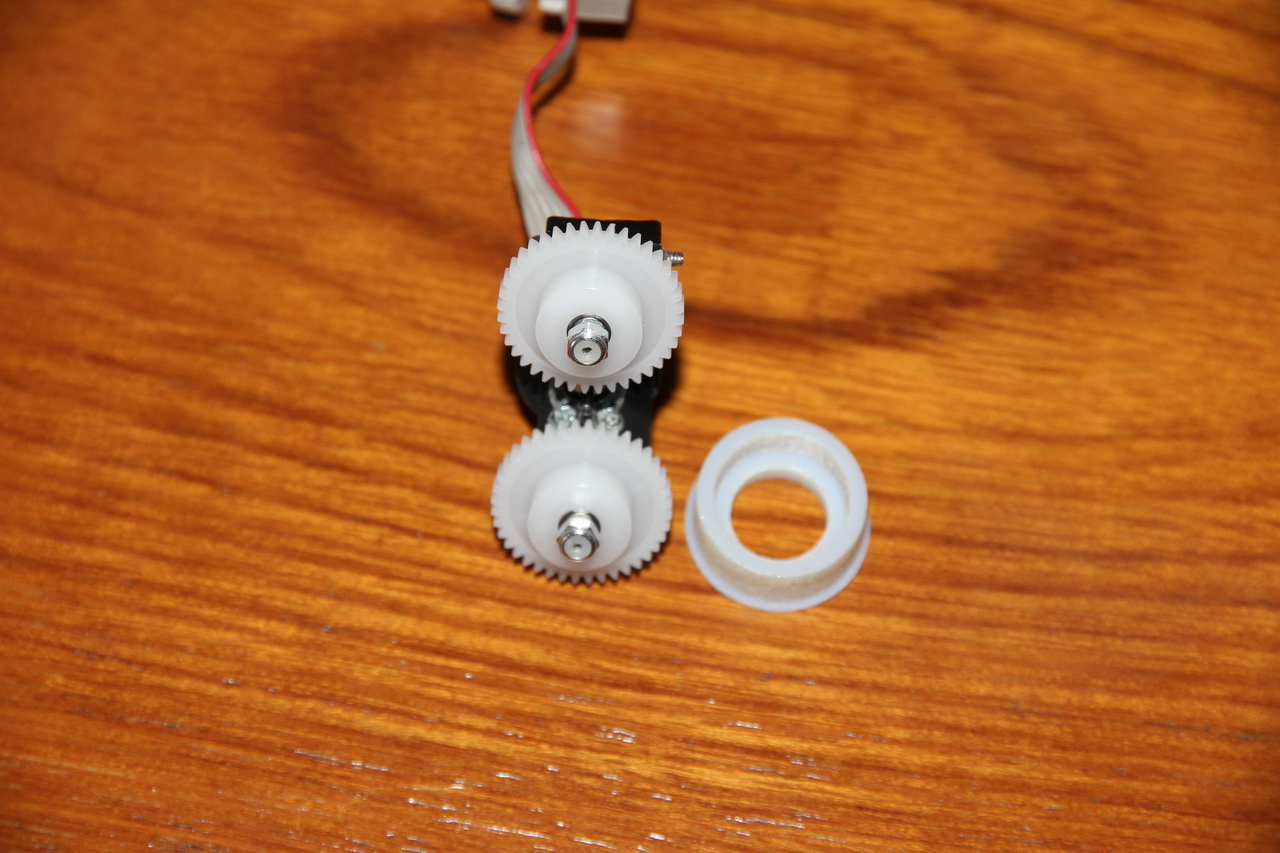

Here are some pictures after I assembled my motor mount with pinion gear and ball bearing, secured by locker nuts.

3D printed wheel that fits the gear perfectly

Sorry, but just a silly question. I’m having a headache while trying to figure out why the 4 wheel micromouse design uses a gear in the middle touching the 2 wheels. I’m maybe too stupid to get it, but does that particular configuration make one wheel go clockwise and the other cuonterclockwise?, sorry, but I simply don’t get it.

no, it doesn’t.

It will make both wheel rotate to same direction.

This is not a silly question, actually a lot of people asked me already 🙂

Thanks, I had to build a similar mechanism with gears from an old printer to check haha … thanks again for the quick response.

How did you determine to make your gears? How were you able to determine the number of teeth!

it’s easy to determine, make the gear ratio as large as possible to gain more torque without trading too much max RPM(depends on your motor specs) as long as the front and rear wheel don’t touch each other. In reality, the ratio maintains between a certain range since you don’t want the front and rear wheel touch each other.

What size OD bearings are you using and may I ask where you bought them from? I am currently having a hard time finding bearings that fit my spur gear that has a 4mm bore size. I have found a few but wanted to see if I could find other options. Thanks

I use 2x5x2.5mm ball bearing

Used the gear with at least 5mm bore.

http://shop.sdp-si.com/catalog/product/?id=A_1M_2MYZ05040

This is the Spur gear I am currently planning on buying since it seems to fit what I need and it’s the only one in stock at a good price

Hello, I have a m2 screw and an mr52zz bearing, but I have the problem that when I insert the screw into the bearing this is very loose even allowing an angle of about 5 degrees, I wanted to know if this is normal or if I chose the wrong components.

Some screw does have much smaller diameter on the thread through the process of the machining.

Where are you buy gears ?

Try misumi usa

How you control the response of the motor.

How did you insert the bearing in the gear? It fits too well. I can’t push it in.

better not to use press to fit type.

use the one with exactly same bore size with metal bonding adhesive.